PINK MOLTEN ALUMINA

Pink Molten Alumina(Low Chromium)

| Size | Al2O3 | Cr2O3 | Na2O | Fe2O3 |

| F012 F014 F016 F020 F022 F024 F030 F036 F040 F046 F054 F060 F070 F080 | ≥98.5 | 0.2-0.45 | ≤0.3 | 0.01-0.05 |

| F090 F100 F120 F150 | ≥98.5 | 0.2-0.45 | ≤0.35 | 0.01-0.05 |

| F180 F220 | ≥98.0 | 0.2-0.45 | ≤0.40 | 0.01-0.05 |

Pink Molten Alumina(Medium Chromium)

| Size | Al2O3 | Cr2O3 | Na2O | Fe2O3 |

| F012 F014 F016 F020 F022 F024 F030 F036 F040 F046 F054 F060 F070 F080 | ≥98.2 | 0.45-1.00 | ≤0.30 | 0.01-0.05 |

| F090 F100 F120 F150 | ≥98.2 | 0.45-1.00 | ≤0.35 | 0.01-0.05 |

| F180 F220 | ≥97.8 | 0.45-1.00 | ≤0.40 | 0.01-0.05 |

Pink Molten Alumina(High Chrominum)

| Size | Al2O3 | Cr2O3 | Na2O | Fe2O3 |

| F012 F014 F016 F020 F022 F024 F030 F036 F040 F046 F054 F060 F070 F080 | ≥97.4 | 1.00-2.00 | ≤0.30 | 0.01-0.05 |

| F090 F100 F120 F150 | ≥97.0 | 1.00-2.00 | ≤0.35 | 0.01-0.05 |

| F180 F220 | ≥96.5 | 1.00-2.00 | ≤0.40 | 0.01-0.05 |

PHYSICAL PROPERTIES(TYPICAL)

| Basic minerals | α-Al2O3 |

| Crystal size μm | 600-2000 |

| True density g/cm3 | ≥3.90 |

| Bulk density g/ cm3 | 1.40-1.91 |

| Knoop hardness kg/mm2 | 2200-2300 |

PARTICLE SIZE DISTRIBUTION

| F012 | +2800um | 0 | +2000um | ≤20% | +1700um | ≥45% | +1700+1400um | ≥70% | -1180um | ≤3% |

| F014 | +2360um | 0 | +1700um | ≤20% | +1400um | ≥45% | +1400+1180um | ≥70% | -1000um | ≤3% |

| F016 | +2000um | 0 | +1400um | ≤20% | +1180um | ≥45% | +1180+1000um | ≥70% | -850um | ≤3% |

| F020 | +1700um | 0 | +1180um | ≤20% | +1000um | ≥45% | +1000+850um | ≥70% | -710um | ≤3% |

| F022 | +1400um | 0 | +1000um | ≤20% | +850um | ≥45% | +850+710um | ≥70% | -600um | ≤3% |

| F024 | +1180um | 0 | +850um | ≤25% | +710um | ≥45% | +710+600um | ≥65% | -500um | ≤3% |

| F030 | +1000um | 0 | +710um | ≤25% | +600um | ≥45% | +600+500um | ≥65% | -425um | ≤3% |

| F036 | +850um | 0 | +600um | ≤25% | +500um | ≥45% | +500+425um | ≥65% | -355um | ≤3% |

| F046 | +600um | 0 | +425um | ≤30% | +355um | ≥40% | 355+300um | ≥65% | -250um | ≤3% |

| F054 | +500um | 0 | +355um | ≤30% | +300um | ≥40% | +300+250um | ≥65% | -212um | ≤3% |

| F060 | +425um | 0 | +300um | ≤30% | +250um | ≥40% | 250+212um | ≥65% | -180um | ≤3% |

| F070 | +355um | 0 | +250um | ≤25% | +212um | ≥40% | +212+180um | ≥65% | -150um | ≤3% |

| F080 | +300um | 0 | +212um | ≤25% | +180um | ≥40% | +180+150um | ≥65% | -125um | ≤3% |

| F090 | +250um | 0 | +180um | ≤20% | +150um | ≥40% | +150+125um | ≥65% | -106um | ≤3% |

| F100 | +212um | 0 | +150um | ≤20% | +125um | ≥40% | +125+106um | ≥65% | -75um | ≤3% |

| F120 | +180um | 0 | +125um | ≤20% | ≥40% | ≥40% | +106+90um | ≥65% | -63um | ≤3% |

| F150 | +150um | 0 | +106um | ≤15% | +75um | ≥40% | +75+63um | ≥65% | -45um | ≤3% |

| F180 | +125um | 0 | +90um | ≤15% | +75um | * | +75+63um | ≥40% | -53um | * |

| F220 | +106um | 0 | +75um | ≤15% | +63um | * | +63+53um | ≥40% | -45um | * |

MAIN APPLICATIONS

—For the surface treatment of pink molten alumina: metal oxide, carbide black skin, metal or non-metal surface rust removal, such as gravity die casting mold, rubber mold oxidation or free agent removal, ceramic surface black spot, in addition to uranium, paint rebirth.

—Beautification treatment: all kinds of gold, gold ornaments, precious metal products of extinction or fog surface treatment, crystal, glass, corrugated, acrylic and other non-metallic fog surface treatment, can make the surface of processing into metallic luster. —Used for etching and processing: jade, crystal, agate, semi-precious stones, seals, elegant stone, antiques, marble tombstones, ceramics, wood, bamboo, etc.

—Precision bond grinding tools, such as ultra-thin cutting disc, cutting wheel, grinding wheel.

—Ceramic grinding wheels such as crankshaft grinding wheel, bowl grinding wheel, cup grinding wheel, installation point, ceramic grinding tools, etc.

—Coat grinding tools, such as sandpaper and polishing wheels.

—High quality firebricks.

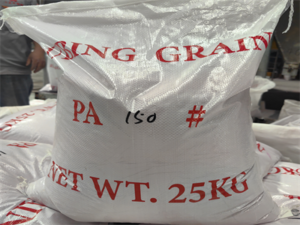

PACKAGING OF PINK MOLTEN ALUMINA

|  |  |  |  |

PRODUCTION LINES OF PINK MOLTEN ALUMINA

|  |  |  |

AVAILABLE SIZES OF PINK MOLTEN ALUMINA

| Fepa | F012 F014 F016 F020 F022 F024 F030 F036 F040 F046 F054 F060 F070 F080 F090 F100 F120 F150 F180 F220 |

| JIS | #12 #14 #16 #20 #24 #30 #36 #40 #46 #54 #60 #70 #80 #90 #100 #120 #150 #180 #220 |